Price: on request

Superwool Plus refractory blanket offers the same benefits as the other members of the Superwool fibre family but with improved handling strength and enhanced thermal properties. Superwool Plus blanket is manufactured from pure raw materials using a new manufacturing technology. In addition to enhanced thermal properties, large nuisance dust particles have been effectively eliminated making the product soft to the touch and less irritating during use. Superwool Plus Blanket is made of long Superwool fibres having the same chemical formulation as the original and well proven Superwool 607 fibre product. It is available in a wide range of thicknesses and densities. It exhibits outstanding insulating properties at elevated temperatures. Superwool Plus blanket has excellent thermal stability and retains its original soft fibrous structure up to its maximum continuous use temperature. Superwool Plus blanket is needled from both sides and possesses high strength before and after heating. Superwool Plus blanket contains neither binder nor lubricant and does not emit any fumes or smell during the first firing. Superwool Plus blanket is flexible, easy to cut and shape and easy to install. (CAS number: 329211-92-9).

Type:

blanket made from high temperature insulation wool.

Classification temperature:

1200 0С / 2192 0F EN 1094-1

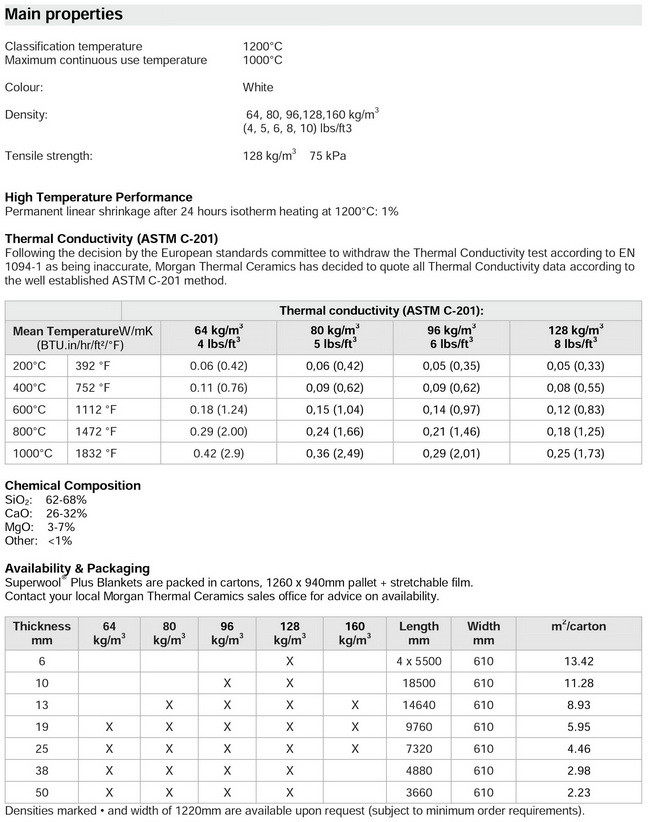

With Superwool Plus fibre, the consistent use of pure raw materials in our factories globally has lead to the 1% shrinkage temperature rising from >1100 0С to >1200 0С. For this reason, the classification temperature is now given as 1200 0С in line with the EN-1094-1 norm. Superwool Plus fibres have been proven over many years to withstand continuous use in an oxidising atmosphere at 1000 0С. This temperature is quoted as the Maximum Continuous Use temperature. For applications above 1000 0С, Morgan Thermal Ceramics recommends Superwool HT® fibre which has a classification temperature of 1300 0С. For further information, contact your local Morgan Thermal Ceramics office.

Typical applications:

• power generation especially HRSG duct insulation;

• chimney insulation;

• process heater linings;

• pipe wrap;

• annealing furnace linings;

• furnace and kiln back-up insulation;

• storage heater insulation;

• domestic oven insulation;

• automotive exhaust heat shields;

• aluminium transfer launder covers.

Benefits:

• exceptional thermal insulating performance compared with industry standards;

• free of binder or lubricant;

• thermal stability;

• low heat storage;

• good resistance to tearing;

• flexible and resilient;

• immune to thermal shock;

• good sound absorption;

• exonerated from any carcinogenic classification under nota Q of directive 97/69EC;

• welding stress relief.

Сlick at the picture to view full size