Price: on request

* price for mortar Blakite. The minimum amount is 20 kg.

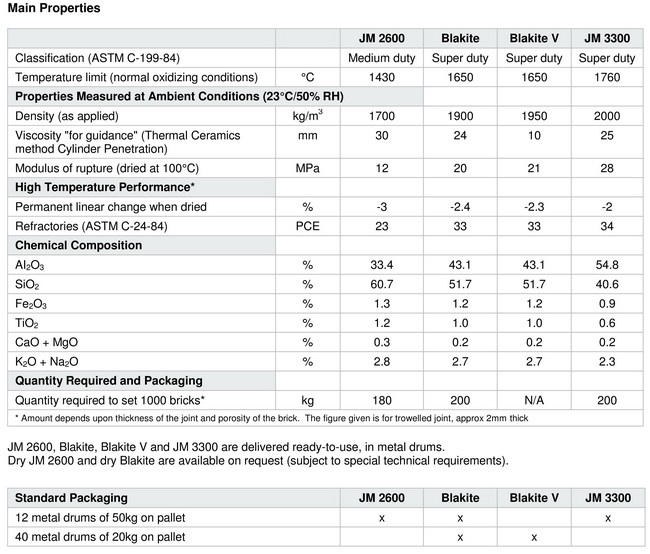

Morgan Thermal Ceramics refractory mortars are normally supplied as ready-to-use wet blends of finelyground aggregates and special binders. Mortars Blakite and JM develop good strength on air drying, forming strong joints and conferring an almost monolithic structure to the brickwork.

Type:

refractory air-setting mortars.

Classification temperature:

JM 2600 - 1430 0С

Blakite - 1650 0С

Blakite V - 1650 0С

JM 3300 - 1760 0С

Maximum continuous use temperature:

the maximum continuous use temperature depends on the application. In case of doubt, refer to your local Morgan Thermal Ceramics distributor for advice.

Available types:

Refractory Mortar JM 2600:

This is an air-setting cement developed for use in lower temperature applications, where a high strength bond is required. It is recommended for mortaring insulating firebricks for operating temperatures up to 1430 0С and can be used for both trowelled and dipped joints.

Refractory Mortar Blakite:

this is a highly refractory mortar, dark grey in colour, which has a high water retention characteristic. It was specially developed for laying insulating firebricks but is also suitable for use with super duty and high alumina dense refractory bricks, at operating temperatures up to 1650 0С. It is supplied in a consistency suitable for shallow patching or trowelling but requires the addition ofapproximately 5% water for dipping. Blakite is a good choice as a single, general purpose mortar on projects involving mainly insulating firebricks but also including some dense firebricks.

Refractory Mortar Blakite V:

this is the standard product with a harder consistency to be used to glue special refractory shapes and steel plates.

Refractory Mortar JM 3300:

a very highly refractory air-setting mortar suitable for laying JM 32 insulating firebricks, and high alumina dense refractory bricks and for operating temperatures up to 1760 0С.

Features:

• good workability, ideal plasticity and water retention;

• low drying and firing shrinkages;

• high refractoriness;

• high bonding strength;

• good resistance to chemical attack;

• stability of chemical components.

Applications:

• for laying insulating firebricks, super-duty and high alumina dense refractory bricks;

• provide resistance to infiltration of air or hot gases;

• hobby and laboratory kilns;

• retard penetration of slag and molten metal into the joints.

Сlick at the picture to view full size