Price: on request

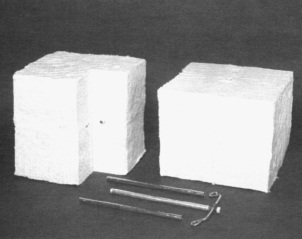

Pyro Bloc refractory modular block comprises two sections of Pyrolog slab in edge-grain orientation. These are held in position with two stainless steel tubes mounted transversely through the modules and remote from the hot face. They are anchored to the furnace casing with the patented Pyro Bloc fixing in any one of four standard versions, Y, M, T and Eye-bolt. In the Y module, the tubes are connected with a central, internal yoke which includes a stainless steel stud and Aluminium extension tube. This version is installed directly onto a metal plate casing, without pre-welding, using the special Pyro Bloc stud gun. It offers the fastest installation rates of any currently available modules. The M module also includes the central yoke, but is fitted onto pre-welded studs using the special M module studlocating equipment. The T module is anchored with a pre-studded, external, sidefix yoke. M and T modules are used where the lining specification calls for either or both a backing blanket and anti-corrosion treatment of the casing. The Eye-bolt version is used for fastening the modules to expanded or perforated metal casings and can also accommodate a backing blanket.

Type:

mechanically-fixed modules.

Classification temperature:

Pyro Blocs are available in 3 density grades in each of two temperature classifications:

Standard Fibre: 1260 0С

Zirconia Fibre: 1425 0С

The maximum continuous use temperature depends on the application. In case of doubt, refer to your local Morgan Thermal Ceramics distributor for advice.

Features:

• high un-compressed densities give low thermalconductivity;

• lubricated fibre allows increased compression and tight joints;

• hardening effect on first firing gives a tough hot face, resistant to mechanical damage and gas flow abrasion;

• resistance to weathering permits limited outside application;

• anchorage remote from the hot face protects steel work.

• Special Shapes

The Pyro-Bloc system allows for modifications, either on site or factory pre-cut, without any directional limitation,to accommodate awkward casing configurations. Lshapedcorner modules provide quick seam-free installation around both internal and external corners, with no need for extra supporting metal work. Half-round cut-away allows fitting to round sections.

• Y Modules

Fast installation

All welds automatically torque tested

One step installation

• M and T Modules

Allow use of backing insulation and casing treatment

Module compression guaranteed

Simple fixing components

Use standard, commercially available welding equipment

• Eye-bolt Modules

Permits fixing of module to expanded or perforated metal casings.

Applications:

Pyro Blocs have a multitude of uses in heat containment applications in all industry groups, a selection of which are as follows:

• Petrochemical (process heaters, reformers, pyrolysis heaters and ductwork)

• Iron and Steel (transfer ladle lids, soaking pit covers, reheating furnace, multi and single stack coil annealing furnaces, continuous annealing and coating furnaces, rotary hearth furnaces, car bottom furnaces, roller furnaces, lift-off furnaces, offtakes and ductwork)

• Aluminium (soaking pits and covers, bale out furnaces, homogenising furnaces, ductwork)

• Ceramic (tunnel kilns for whiteware and red brick, intermittent kilns for whiteware and red brick, Hoffman kilns and ductwork)

• Utilities (thermal oxidisers, waste heat recovery units, combustion chambers and boiler ductwork)

Fixing components and installation:

The standard tubes and yokes for all Pyro-Blocs are ASTM 316 stainless steel, but higher grades of steel (ASTM 310 or Inconel 601) are available for more arduous service conditions. Studs are ASTM 304 stainless steel or of such higher grade which are warranted by the service conditions. Full details of the installation of all Morgan Thermal Ceramics modules are included in our Module Installation Manual.

Availability and packaging:

Pyro-Blocs are normally supplied as 305mm square and of thicknesses ranging from 100mm to 350mm, in 25mm increments.

Other sizes, shapes and densities, including L-shaped modules can be made available on request.

Pyro-Blocs are delivered packed either in cartons 315mm square x 930mm long or on palleted jumbo cartons, 1250mm x 1110mm x 1100mm high (including pallet).

Сlick at the picture to view full size