Price: on request

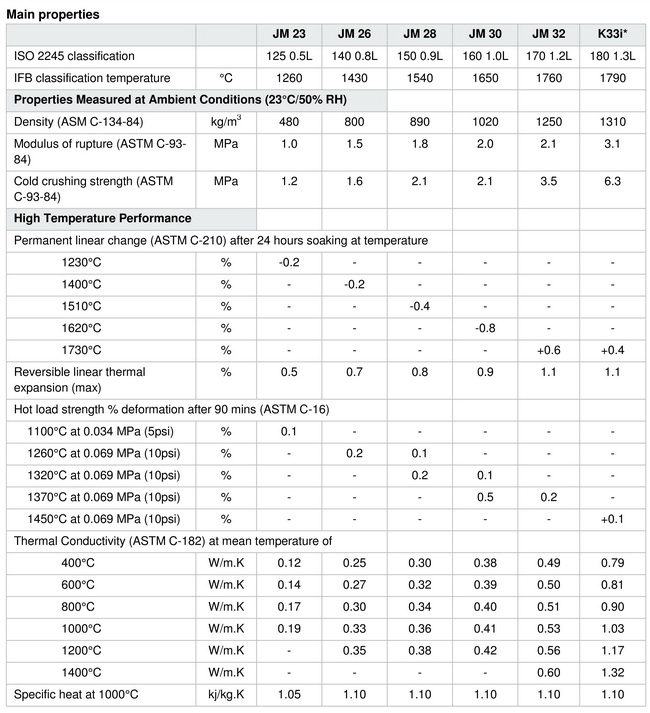

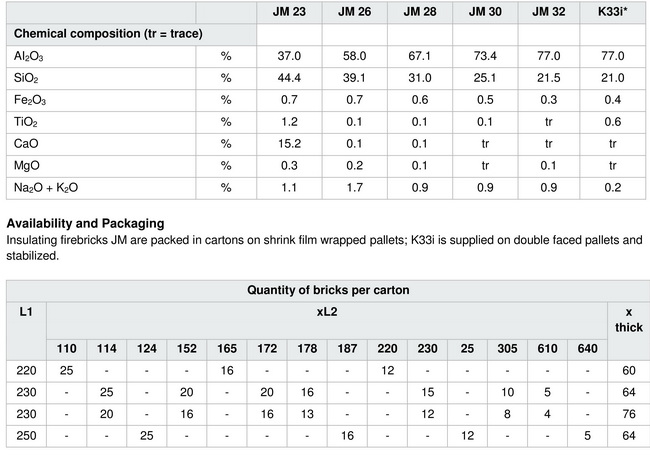

Morgan Thermal Ceramics produces 5 grades of insulating firebricks with limiting temperatures of use ranging from 1260 0C to 1760 0C. Each grade is formulated to meet specific thermal and physical requirements. JM Firebricks are made from high-purity refractory clays, with graduated additions of alumina for the higher temperature products, and a carefully graded organic filler, which burns out during manufacture to give a uniform, controlled pore structure. Each brick is machined to precise tolerances on all 5 faces. Morgan Thermal Ceramics also produces a range of mortars to suit the different grades of brick.

Тype:

insulating firebricks.

Classification temperatures from:

1260 0C up to 1760 0C

Maximum continuous use temperature:

The maximum continuous use temperature depends on the application. In case of doubt, refer to your local Morgan Thermal Ceramics distributor for advice.

Features:

• low thermal conductivity - gives good thermal insulation, enabling the use of thinwalled constructions;

• low heat storage - due to their light weight and low thermal conductivity, JM bricks absorb minimal heat, giving significant energy savings in cyclically-operated kilns;

• purity - the very low iron and alkali flux content confers good refractoriness and the high alumina content contributes to their stability in reducing atmosphere;

• high hot compressive strength;

• the accurate dimensions - enable the bricks to be laid more quickly, with thin, uniform joints, allowing the construction of strong and stable structures;

• large bricks or slabs - they are available in sizes 230 x 610 x 64 or 76mm and 250 x 640 x 64mm. These can be machined into special shapes, incurring fewer sections and joints;

• purpose-designed packaging - protects the bricks in transit (in cartons containing 4 to 25item, depending on shape) and facilitates on-sitehandling.

Typical applications:

recommended for use as a primary hot face refractory lining or as back-up insulation behind other refractories infurnaces, kilns, flues, refining vessels and heaters, regenerators, gas producers and main, soaking pits, stress relieving furnaces, reactor chambers and similar high temperature industrial equipment.

Special shapes:

in addition to the standard brick sizes, JM insulating firebricks are available in pre-machined special shapes. The blanks for very large shapes are formed by mortaring together two or more JM slabs, the unique large sizes of these slabs ensuring the least number of sections and joints in the finished article.

Сlick at the picture to view full size