Year: 2015

Country: Ukraine

Industry: Production of ceramics and building materials

In March 2015, our lining specialists performed a rebuilding project of lining of the arch of the tunnel furnace of roasting of a brick. Works were carried out in several steps:

- development of design and estimate documentation on reconstruction of lining of the arch of the tunnel furnace of roasting of a brick;

- surface preparation of a metalwork of the arch of the furnace (sand-blasting and painting);

- mounting of a basic metalwork of the arch of the furnace;

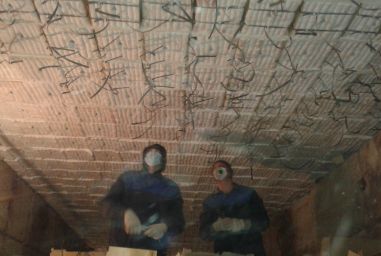

- stud welding (heat resisting fixture) for lining;

- mounting of lining of the arch of the furnace.

For the purpose of achievement of essential saving of costs of energy carriers in the course of operation of the furnace, at lining the arch of the furnace the newest lining materials of the leading global manufacturer of Shandong Luyang Share Co were applied. These are lightweight (materials on the basis of ceramic fiber) - LYTX-1260M modules, boards LYTX-164B, mats (blankets) of LYTX-312 and LYTX-212, and also fixing materials are applied to lining from creep-resisting steel (heat resisting fixture). These lining materials possess excellent resistance to thermal blows, low coefficients of heat capacity and heat conductivity, are long-lasting and competitive at the price in comparison with standardly applied outdated lining materials of a domestic production (a chamotte brick and so forth).

Reconstruction of lining of the arch of the furnace was carried out according to technical regulations, qualitatively, in full and in time. It is also necessary to tell that works are performed by highly qualified specialists (designers, estimators, lining masters, etc.) which constantly are trained by leading companies of the industry. So, for example, stud welding (heat resisting fixture) was carried out by the high-performance device of arc welding for the purpose of achievement of the most reliable and fast welding, and also the minimum expense of heat resisting fixture. The main objective of reconstruction of lining of the arch of the furnace - achievement of essential saving of energy resources, and our company successfully coped with the task set by the customer.

Other projects