Price: on request

FireMaster blanket is a non-combustible, flexible matt manufactured from alkaline earth silicate fibres suitable for use in both cellulosic, hydrocarbon and jet fire protection applications. The patented fibre formulation used gives enhanced solubility in the human body together with excellent thermal and acoustic properties. FireMaster blanket has the same appearance as Refractory Ceramic fibre and can be used in the same range of fibre protection applications with equivalent thermal insulation performance. No binders are used during manufacture thus there is no risk of smoke or toxic gas emission or loss of strength during a fire due to binder burn out. FireMaster is easy to handle being flexible and resilient with good tensile strength. No special installation tools are needed and the blanket can be cut with a sharp knife. The blanket is supplied in rolls each marked with key production data, packed in a specially printed carton. A significant number of fire tests have already proven the performance of the FireMaster® blanket for up to 4 hours in hydrocarbon fires and one hour in jet fires. Fire protection is achieved with lower thickness and weight than with other Mineral Fibre compositions.

Type:

refractory fibre blankets.

Features:

• Colour : white with key production data printed on surface.

• Linear shrinkage (24 hrs at 1000 0C) <1%.

• Loss on ignition (5 hrs at 1000 0C) <0.1%.

Fire protection properties:

• Non-combustibility: IMO A799 (19) using ISO 1182-1990 (E) method.

Approved product number under EU Marine Equipment Directive: 0062.

All other properties of FireMaster® blanket will be as the ceramic fibre based FireMaster blanket, which are detailed in the following sections.

Fire hazard properties per ASTM E-84 method:

• Flame spread: zero.

• Fuel contributed: zero.

• Smoke developed: zero.

FireMaster blanket is inert and resistant to mould growth and attack by vermin.

Applications:

• ‘A’ class and IMO HSC steel, aluminium and PVC composite bulkhead and deck insulation in high speed craft.

• Upgrading of fire performance of composite panels to meet IMO room corner test requirements.

• H class and A class steel bulkhead and deck fire protection for ships and offshore platforms.

• Hydrocarbon and Jet fire protection of process pipes and vessels.

• Infill to fire doors and cladding panels.

• Construction joints.

• Cellulosic and hydrocarbon fire protection of structural steelwork.

• Ductwork fire protection.

• Cable tray fire protection.

Сlick at the picture to view full size

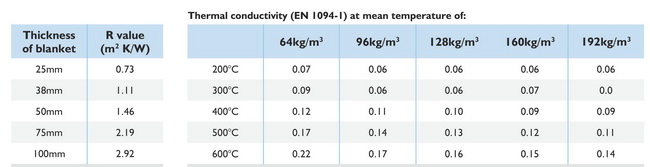

Basis : thermal conductivity of 96 kg/m3 density measured at 20 0C to BS 874 of 0,0342 W/mK.