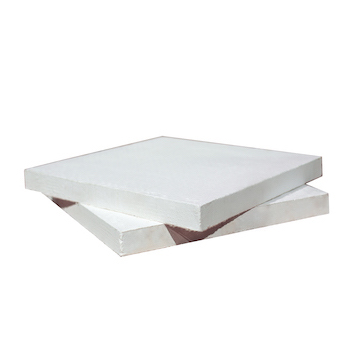

Refractory board LYTX

Refractory board LYTX

Refractory boards Morgan Advanced Materials

Refractory boards Morgan Advanced Materials

Calcium-silicate board

Calcium-silicate board

Chamotte board

Chamotte board

Heat-resistant boards made of high-quality ceramic fiber with the binders addition, have a variety of excellent thermal and physical properties. This product is produced by the world-famous companies Morgan Advanced Materials and Luyang Unifrax Trading Company Limited, which use modern equipment and innovative technological processes. Experts of Morgan Advanced Materials and Shandong Luyang Share Co thoroughly control the product quality at all production stages. Thanks to the above, heat-insulating boards in terms of their thermophysical characteristics significantly exceed the standard refractory board’s analogues (basalt boards, mullite silica boards, etc). And taking into account the competitive prices, heat-resistant board has become a high-demand product for thermal equipment insulation and lining.

Refractory board has the following features: installation capability upon the first (open) or the second (insulation) layer, resistance to the temperature shocks, structure homogeneity, durability, strength, simple installation and machining, and others.

Specified characteristics of refractory boards facilitate their successful usage as a thermal insulation, insulating or fireproof layer during the lining of boilers, furnaces, chimneys, flues and other equipment.

Thus, the refractory board application in production processes enables to improve the energy efficiency of high-temperature equipment and significantly reduce the energy costs.

You can buy refractory boards by selecting the type of board of interest and filling out the order form.