Year: 2014

Country: Ukraine

Industry: Mechanical engineering, metalworking and pipe-rolling production

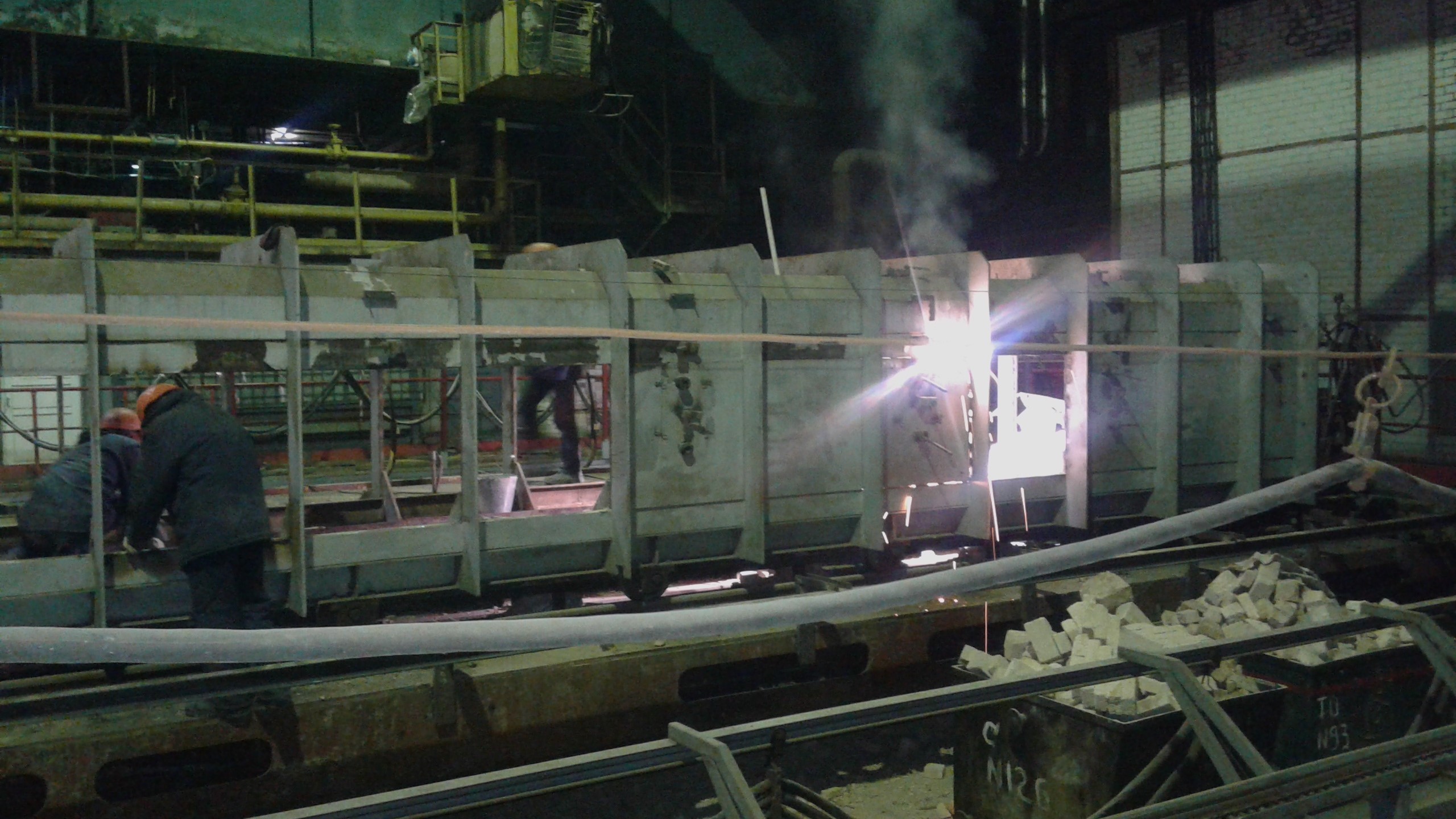

In November - December, 2014 our company has carried out a complex of works of reconstruction of the muffle thermal furnace of resistance of tube rolling plant, in particular has executed:

- development of the project of reconstruction of the furnace, including estimate documentation;

- partial dismantling of a metalwork of a framework and full dismantle of the existing lining of the furnace;

- mounting of a metalwork of a framework;

- stud welding for fixture of lining;

- putting anticorrosion coating;

- mounting of lining of the furnace;

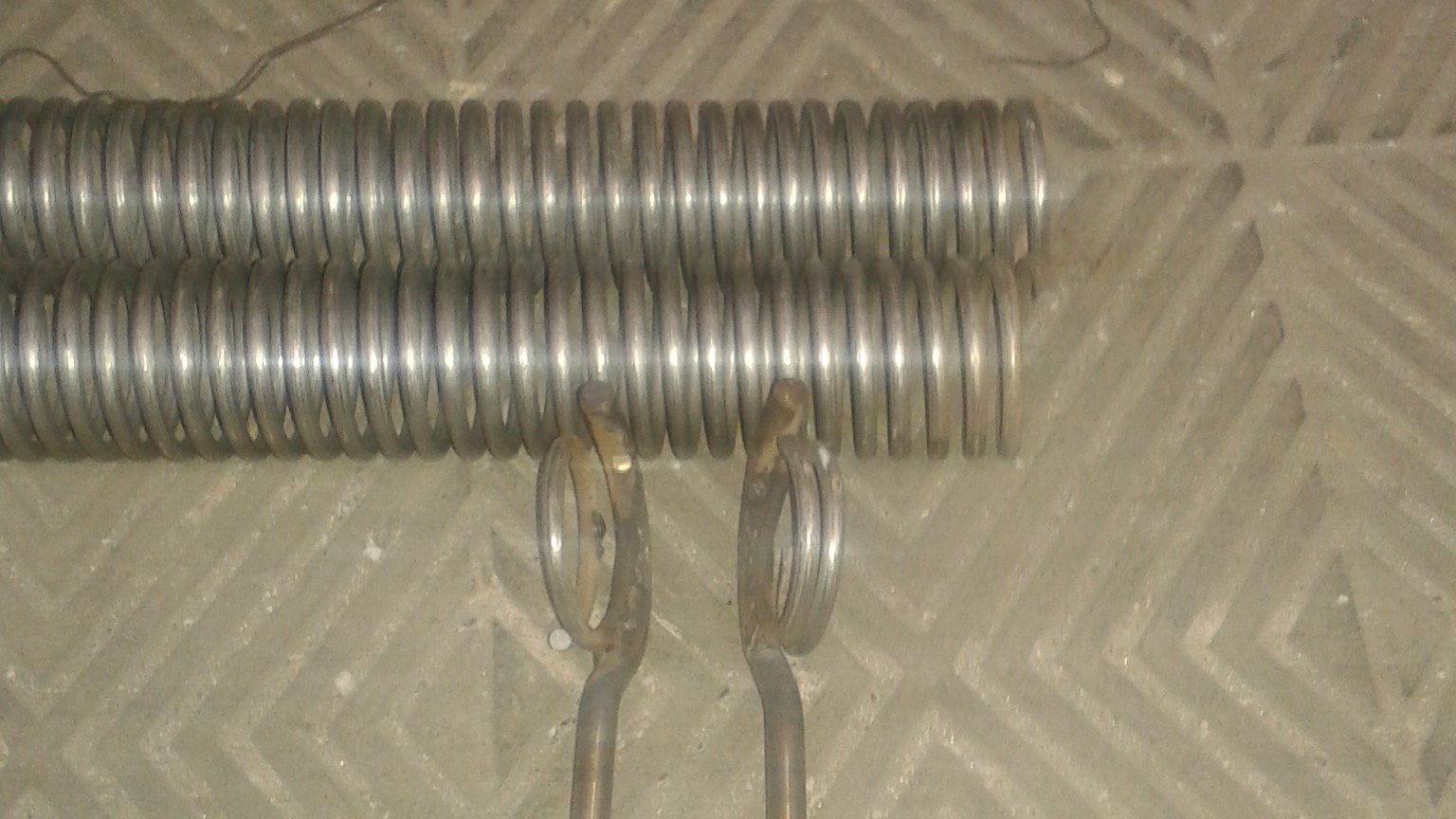

- assembly and mounting of heating elements for the furnace;

- mounting of inputs of thermocouples in lining of walls of the furnace;

- mounting of panels of the arch of the furnace;

- mounting of isolation of a rack of the muffle, lining of a valve and mounting of a valve on the muffle;

- assembly and connection of a cabinet of an automatic control system;

- commissioning work.

At reconstruction of the furnace the latest lightweight materials on the basis of ceramic fiber - module LYTX-1260M, board LYTX-164B, mat (blanket) of LYTX-312, LYTX-212, LYTX-236B paper, textiles of LYTX-208A2, mortar Blakite, a fire-brick of ShL-0,4 and ShL-1,3 were used, and also modern materials of heating elements are applied to the furnace - the spirals from a wire Resistom 145 wound on ceramic tubes of MKR. Works were carried out according to technical regulations, in full, qualitatively and in due time as evidenced by the appropriate review.

Results of reconstruction of the furnace:

- considerable power saving in the course of heat treatment of corrosion-proof pipes;

- total weight of lining of the furnace was reduced almost by 2,5 times, at the same time all heatphysical indicators and productivity of the furnace improved;

- resistance to thermal blows improved and the temperature range of operation of the equipment - from 800 C0 to 1150 C0 extended.

Other projects