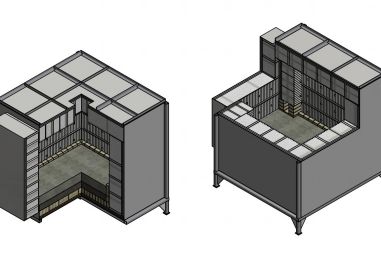

Having received the order for performance of work on a major repair of lining of the furnace our company developed the corresponding project and implemented it.

Main objectives of a major repair of the furnace:

- decrease in energy costs;

- decrease in total weight of lining;

- improvement of thermalphysic properties of the furnace.

“Inventum Ukraine” successfully realized a large number of different projects on modernization of thermal units, including linings and thermal insulations. Therefore for accomplishment of the tasks set by the customer, specialists of the company made the decision to apply modern refractory materials and including lightweight materials on the basis of ceramic fiber.

To lining of side walls, a valve and a furnace roof, were applied: heat-insulating mat LYTX and refractory modular block LYTX. The heat-insulating mat LYTX was used as a substrate, and refractory modular block LYTX - as the main fire-resistant layer of lining. The refractory modular block LYTX has a set of advantages, such as: simplicity in mounting, the small weight, resistance to gas flows, low heat conductivity, durability and others.

Under furnaces is lined by a low-cement concrete and concrete of average weight of production of the Morgan Advanced Materials company, heat-insulation layer - a fire-resistant plate of Superwool Plus Blok.

Application of multilayer construction from modern fire-resistant materials, including on the basis of ceramic fiber, allowed to cope with the tasks set by the customer excellently.

Other projects