In 2019, the company "Inventum Ukraine" carried out a complete overhaul of lime burning furnace TWIN-D 55 "Cimprogetti". The works were performed in strict accordance with the provided technical documentation of the customer. The goal of our company was to carry out the whole amount of work in the shortest possible time:

• dismantling of the old lining (about 180 m3);

• repair of steel constructions;

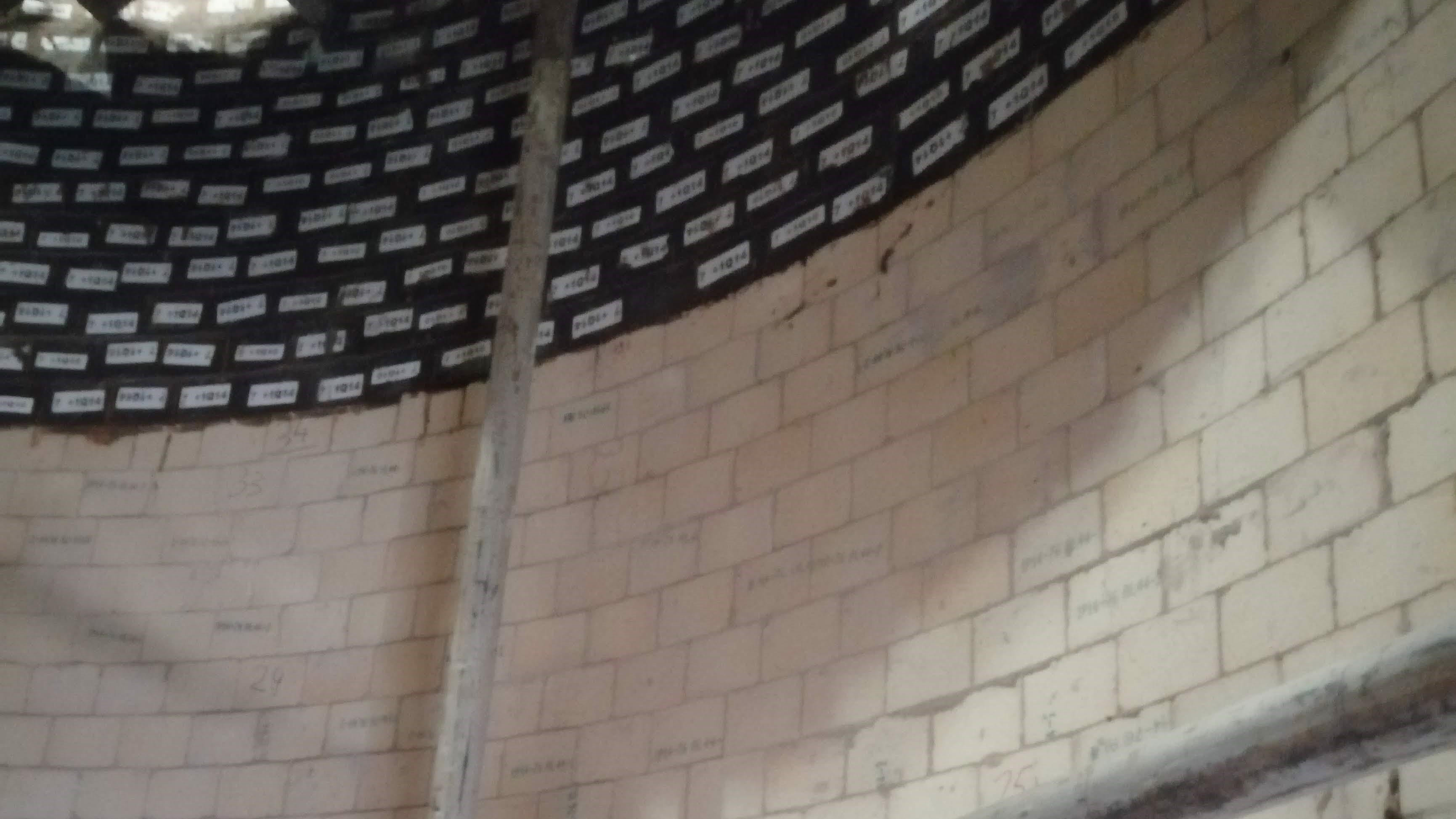

• mounting the lining (insulating, reinforcing and refractory layers).

Having installed the necessary equipment, the specialists of our company started dismantling works and repair of steel constructions of the furnace. Also, new access hatches for the customer's service staff were installed. After that the next phase of furnace complete overhaul was started, it is mounting insulating, reinforcing and refractory layers of lining. At this phase, our specialists were especially attentive, as the refractory bricks had many different configurations, of more than 40 types. No less responsible was the masonry itself - the joints had to conform to technical specifications. Upon completion of the mounting the lining, we installed the required number of thermocouples and started the commissioning of the equipment.

To accomplish this type of work, including refractory masonry of industrial furnaces, our company has the required staff of qualified employees (technical specialists, refractories engineers, installers), as well as its own equipment stock (stone-cutting machines, concrete mixers, mixers, large reserves of construction timber and other equipment).

A complete overhaul of the lime burning furnace was performed in full scale and in advance of the approved schedule. The customer has given appropriate feedback about the accomplished work.

Other projects