In 2018, our company completed a project to overhaul the refractory lining of the firing machine. The works were performed according to the project submitted by the customer and the required technical documents. Repair of the lining was carried out over several months, and included two main stages: dismantling of the old lining and installation of a new one.

Dismantling the outdated lining included:

- Demolition of refractory brickwork;

- Disassembly of the refractory concrete lining;

- Disassembly of insulation of plates and felt;

- Demolition of the suspended arch;

- Cleaning and preparation of metal structures.

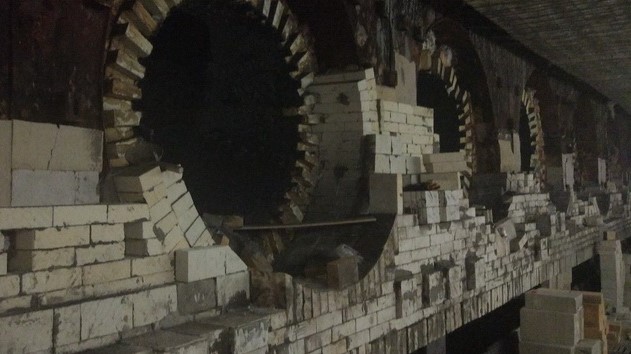

Having completed all the dismantling and preparatory work, Inventum Ukraine specialists began the installation of the insulation layer. The insulation was made of mullite-corundum plates and felt. The wall surface of the cooling zones was hardened with refractory concrete. The walls of the furnace, hearth and arches are lined with a multi-layer construction. The main layers are made of MKS refractory bricks; the insulating layer is made of lightweight chamotte products. We carried out constructive cutting of MKS heavy bricks, SHA and SHL bricks for arc and cylindrical laying using special equipment. The overhauling of the refractory lining was very labour-intensive, part of the work was carried out at a height of about 12m.

Our company has successfully completed all the necessary work on the overhaul of the refractory lining of the firing machine. The works were performed according to the project, in full and on time.

Other projects