Price: on request

Superwool HT Felt is an insulating felt, obtained by hot pressing. It is made from Superwool HT fibres, bonded with an organic binder which begins to burn out at 180°C. This special binder makes Superwool HT Felt particularly suitable for die-cutting operations. Semi rigid, it is neither brittle nor dusty. Superwool HT Felt optimises the manufacture of complex, die-cut shapes to close tolerances. Made from chemically stable fibres, lightweight and very insulating, Superwool HT Felt is a multi-purpose product.

Type:

felt manufactured from high temperature insulation wool.

Classification temperature:

1300 0C (ENV 1094-3)

The maximum continuous use temperature depends on the application. Unaffected by most chemicals except strong alkalis, phosphoric acid and molybdenum. For further advise please contact your local Morgan Thermal Ceramics partner.

Features:

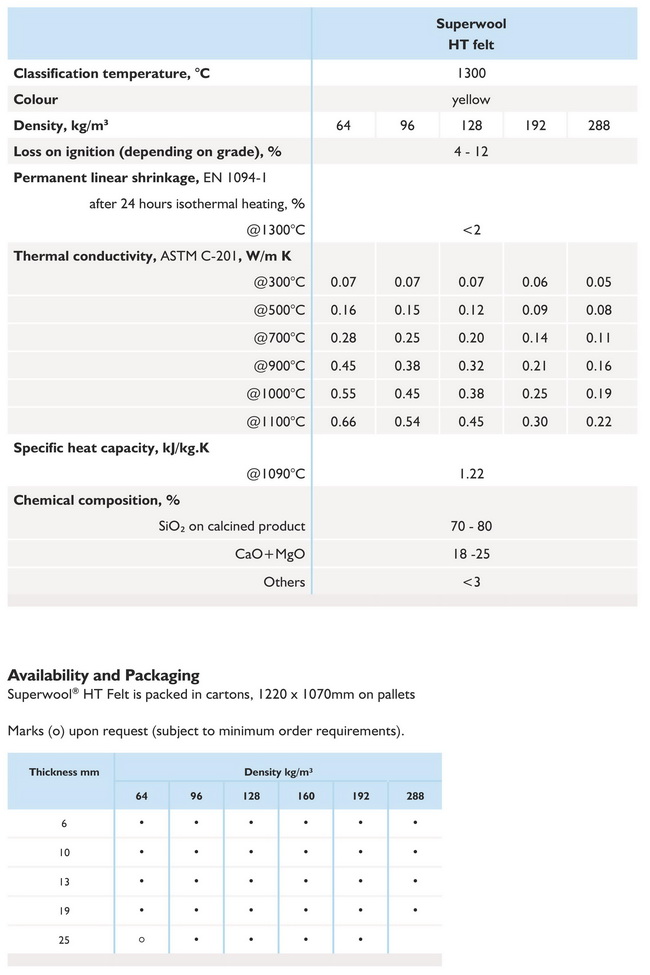

• wide range of densities: eight grades from 64kg/m³ up to 288kg/m³;

• high temperature resistance;

• low thermal conductivity;

• particularly suited to cutting operations (with saw, water jet or by stamping);

• flexible or semi-rigid, depending on density selected;

• chemically stable;

• high sound absorption properties;

• precise thicknesses;

• resistant to thermal shock;

• low heat storage;

• no reaction with alumina based bricks in application in the range of the typical use temperature;

• exonerated from any carcinogenic classification under nota Q of directive 97/69EC.

Typical applications:

• die cut shapes for domestic appliances;

• thermal barrier media;

• insulating thermal break;

• high temperature gaskets;

• expansion joints for furnace, kiln and boiler linings.

Сlick at the picture to view full size