Price: on request

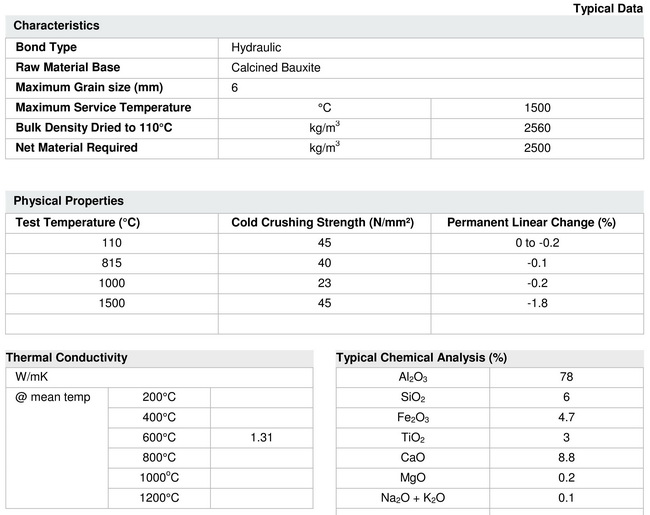

A 1500 0С high alumina castable with excellent working properties, high strength and good abrasion resistance and thermal shock resistance (up to 1500 0С).

Applications:

excellent general purpose castables for both heat containment and metal contact.

Features and Benefits:

• conventional dense, general purpose, bauxite based castable for temperatures up to 1500 0С.

• superior characteristics have made this product a firm favourite in a vast range of applications worldwide.

Installation method:

casting.

Instructions for use:

highest strength is obtained with monolithic refractory by using the least amount of clean mixing water. This will allow thorough working of material into place by vibrating or rodding. A mechanical mixer is required for proper placement (paddle-type mortar mixers are best suited). After achieving a ball-in-hand consistency, mix for >4 minutes. Place material within 30 minutes after mixing.

Data sheet:

prepared using EN BSI and ISO standard Methods.

Storage:

store bagged monolithics in a dry place, off the ground and, when possible, with the original shrink wrapping intact.