Price: on request

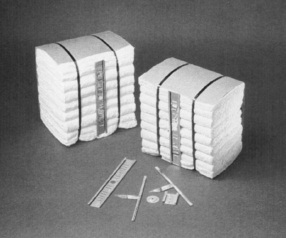

Z-Blok modular refractory blocks are lightweight, insulating linings made in block form for direct attachment to industrial furnace and kiln shells. Z-Blok modules are designed to simplify and speed up furnace lining installation while providing a wide range of significant operating benefits. Z-Blok refractory fibre modules are formed from three basic components:

• An insulating portion consisting of an accordion-pleated, continuous piece of Morgan Thermal Ceramics refractory fibre materials: Cerablanket, Cerachem or Cerachrome Blanket.

• Stainless steel reinforcement and mounting hardware made up of beams positioned within the folds and connected by tabs to a channel on the cold face of Z-

Blok module. The channel is designed to slide freely on the stainless steel clip which is attached to the furnace shell.

• Compression banding to restrain the block in a 305 x 305mm dimension.After attachment to the furnace shell in a parquet pattern,the compression restraints are removed and the refractory fibre expands. This produces a tight, gap-free insulating furnace liner with all metal parts isolated from high temperatures because of their position adjacent to the cold face

Type:

refractory Fibre Blankets in Modular Block Form.

Maximum continuous use temperature:

Мат Cerablanket - 1260 0C

Мат Cerachem - 1425 0C

Мат Cerachrome Т - 1425 0C

The maximum continuous use temperature depends on the application. In case of doubt, refer to your local Morgan Thermal Ceramics distributor for advice.

Available forms:

• Z-Blok refractory fibre modules are furnished in a number of different configurations depending on service requirements;

• the choice of the type of Blanket used in the construction of Z-Blok modules should be determined by the characteristics and operation of the furnace equipment to be lined. Operating temperature (steady or cyclic), nature of ware, energy used (electricity or type of gas or oil), furnace atmosphere, etc are some of the factors that must be taken in to account. We would recommend, for the optimum blanket selection that the Morgan Thermal Ceramics expert, and/or local representative, be consulted in the initial stages of lining design.

Advantages:

A Z-Blok furnace offers the furnace user, as well as the builder, many advantages:

• fast installation;

• efficient attachment design;

• gap-free lining;

• immediately available for operation;

• lightweight;

• low heat storage;

• thermal shock resistance;

• mechanical shock resistance;

• resilient.

Components:

The Z-Blok module is composed of accordion-pleated Cerablanket, Cerachem or Cerachrome Blanket, with 8 pleats, and an attachment system.

• clips and channels are Type 304 stainless steel;

• support beams are Type 321 titanium reinforced and completely encased in pleats of refractory fibre;

• tabs are attached to beams and penetrate pleats;

• tabs are attached to channels on outside of block;

• there are two types of attachment clips that are fastened to furnace shell, rectangular clip and washer;

• channel slides into clip. Channel slides over washer.

Installation:

The Z-Blok system speeds refractory fibre blanket installation because the blanket is pre-fabricated into modules thatattach to the furnace in one step.

Z-Blok modules are installed by simply sliding them into place, passing the channel at the back of the Z-Blok modulethrough the attachment clip or washer previously positioned on the shell of the equipment being lined.

There are several acceptable ways to fasten the attachment clip to a furnace shell:

• powder-actuated fasteners;

• welded fasteners - studs of cotter key-life pins;

• bolts and nuts, self-tapping screws or pop rivets (these require the shell to be pre-drilled);

Sizes:

Z-Blok modules measure 305 x 305mm and are available in the following thicknesses: 102, 127, 152, 178, 203, 229, 254, 280 and 305mm.