Price: on request

Z-Blok 1 are refractory modular blocks made from high quality spun-fibre blanket, folded and pre-compressed toa specified density. The fixing system comprises two beams positioned within the folds and connected by tabs to an exterior channel, mounted transversely and centrally across the back of the modules. During installation, the modules are further compressed, the resilience of the fibre and recovery after the recovery after the restraining bands are removed ensuring tightly-compressed intermodular joints.

Type:

convoluted anchor modules.

Maximum continuous use temperature:

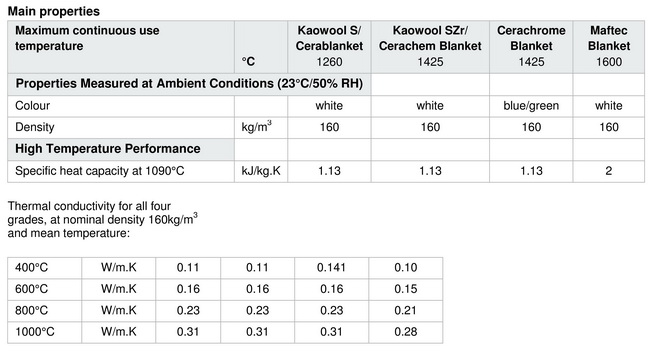

Kaowool S/Cerablanket fibre - 1260 0C

Kaowool SZr/Cerachem Blanket - 1425 0C

Cerachrome Blanket - 1425 0C

Maftec Blanket - 1600 0C

The maximum continuous use temperature depends on the application. In case of doubt, refer to your local Morgan Thermal Ceramics distributor for advice.

Features:

Z-Blok 1 modules offer several advantages to both the furnace constructor and the end-user.

• the anchorage on the back allows for both in-line and parquet installation;

• the decompression of the blanket folds gives tightly sealed intermodular joints with both configurations;

• the resilient blanket is resistant to mechanical damage;

• the resilience of the blanket can accommodate some flexure of the furnace casing without opening gaps between modules;

• light weight, giving low heat absorption in the insulation;

• low thermal conductivity giving high thermal efficiency;

• total resistance to thermal shock;

• no drying or curing required - so available for production operation immediately after installation;

• the anchor system is remote from the module hot face, maintaining the metal components at a relatively low temperature;

• the anchor system can be secured to the furnace casing with a variety of fasteners: power activated fasteners, welded studs or cotter key-life pins, nuts and bolts, self-tapping screws or pop rivets.

Applications:

Z-Blok 1 have a multitude of uses in heat containment applications in all industry groups, a selection of which are as follows:

Petrochemical (process heaters, reformers, ductwork pyrolysis heaters);

Iron and Steel ( transfer ladle lids, soaking pit covers, reheating furnace, multi and single stack coil annealing furnaces, continuous annealing and coating furnaces, rotary hearth furnaces, car bottom furnaces, roller furnaces, lift-off furnaces, offtakes and ductwork);

Aluminium (soaking pits and covers, bale out furnaces, homogenising furnaces and ductwork);

Ceramic (tunnel and intermitted kilns for whiteware, sanitary ware and brick firing Hoffman kilns, kilns for firing technical ceramics, insulation for ducts and fires);

Utilities (thermal oxidisers, waste heat recovery units, combustion chambers and boiler ductwork).

Fixing components:

These are supplied with the module and comprise:

• support beams in ASTM 321 stainless steel;

• clips and channels in ASTM 304 stainless steel;

• attachment clips of either of two types: rectangular or washer;

Fixing components can be supplied on request or for operation in exceptional conditions.

Dimensions & Availability:

The modules as normally supplied are 305mm square and thickness ranging from 100mm to 350mm in 25mm steps.

Other sizes and densities can be made available on request.

Packaging:

Z-Blok 1 are packed in cartons or on pallets which are shrink wrapped.

Installation:

Full details of the recommended technique for installing Morgan Thermal Ceramics modules are included in our Module Installation Manual.

Сlick at the picture to view full size