Price: on request

Low cement castable with exceptionally high fluidity, allowing installation of the most intricate shapes with minimal vibration. Exhibits thermal shock resistance (up to 1650 0С), ultra high strengths, low porosity, excellent thermal shock and abrasion resistance.

Applications:

• forge furnace hearths;

• door jambs, lintels and piers;

• cartops;

• rotary kiln nose rings, retainer rings and dams;

• rotary hearth curbs;

• walking beam furnace hearth, pusher furnace hearths;

• skid pipe protection.

Features and benefits:

• ultra high-strength low cement monolithics;

• low porosity;

• excellent abrasion resistance;

• excellent thermal shock resistance.

Installation method:

casting.

Instructions for use:

highest strength is obtained with monolithic refractory by using the least amount of clean mixing water that will allow thorough working of material into place by vibrating. A mechanical mixer is required for proper placement (paddle type mortar mixers are best suited). After adding the recommended amount of water, mix for 4-6 minutes. Place material within 20 minutes after mixing.

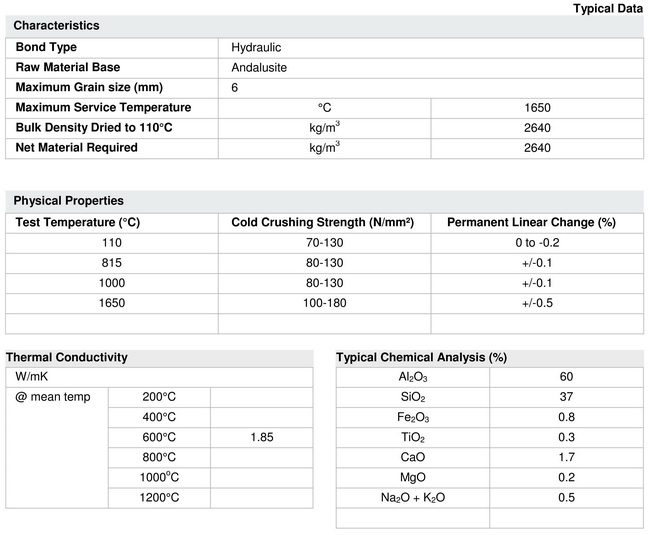

Data sheet:

prepared using EN BSI and ISO standard Methods.

Storage:

store bagged monolithics in a dry place, off the ground and, when possible, with the original shrink wrapping intact.