Price: on request

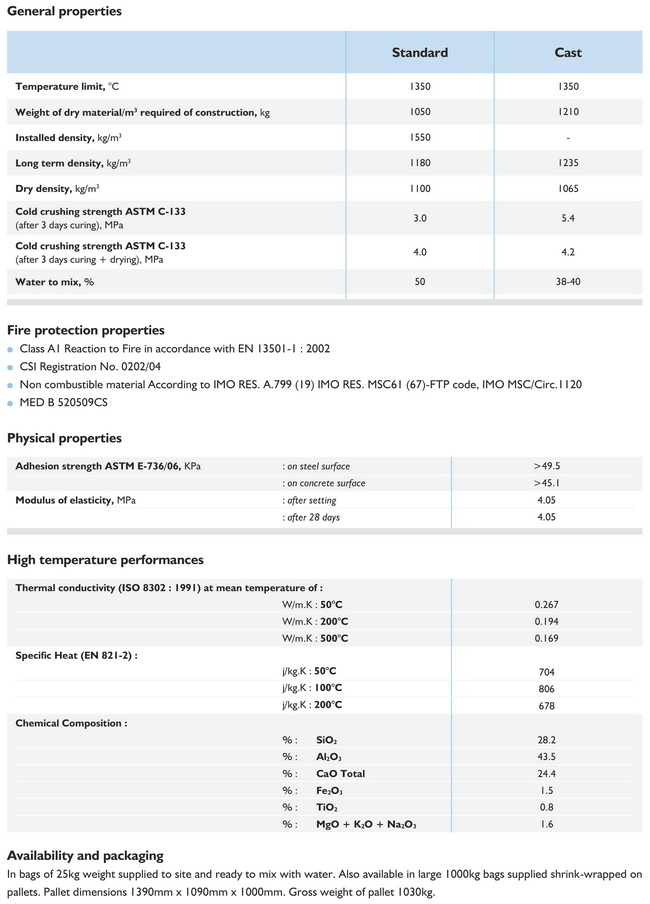

FireMaster FireBarrier products are cementitious materials designed for a variety of fire protection applications requiring strong and weather resistant exterior finishes. FireBarrier 135 is available in two different dry powder versions used for either spayed or cast application. The dry powder is mixed with water, either in a spray machine forsprayed application, or directly when cast into shapes. The cast version allowsliningsto be pre-formed when spray application is not convenient or practical. Consisting of a unique formulation of Morgan Thermal Ceramics refractory echnology. FireMaster FireBarrier when mixed with water can be applied by spray equipment to a variety of substrates. FireMaster FireBarrier 135 is suitable for cellulosic and hydrocarbon fires and has been fire tested in high-rise hydrocarbon fires of up to 1350 0С. FireMaster FireBarrier135 has been successfully fire tested to IMO A 754(18), ISO 834, RABT, Hydrocarbon modified (HCM) and RWS fire curves.

Features:

• 2 versions available: one for sprayed application and one for cast application;

• very low spraying wastage during installation – less than 1% of weight;

• fast and easy to install - one, single layer application;

• high adhesion strength - eight times greater than product weight;

• high quality surface finish that can be painted;

• fireBarrier 135 (*Patent No. 98830682.5);

• refractory product capable of repeated exposure to 1350 0С (2462°F).

Comprehensively fire tested in over 11 fire tests for fire protection oftunnels EU MED approved A60 steel floating floor system

Applications:

• tunnel fire protection (concrete linings, escape refuges, ventilation shafts);

• A60 floating floors in ships.

Сlick at the picture to view full size